-

Case Study

Why Tonn and Blank Chose to Integrate Sage 300 CRE With Align to Minimize Waste and Improve Productivity

Overview

For over 100 years, Tonn and Blank Construction put their stamp on the state of Indiana, largely thanks to a culture of innovation. It is no secret that the construction industry faces significant operational challenges today, including a limited workforce, supply disruptions, and volatile costs, which have forced many companies to pursue streamlined operations to combat those issues. Tonn and Blank dedicates time, staff, and budget to empower its employees to improve processes to work more efficiently, whether it’s maximizing software utilization, or off-site construction prefabrication, in order to drive productivity and profitability.

Tonn and Blank adopted and practices lean construction, not as a reaction to recent events but as an operating philosophy that they embraced for decades to stay ahead of the competition.

In the 1950s, Tonn and Blank was one of the first to prefabricate homes and have its own concrete mix facility on site. In 2012, Tonn and Blank implemented our Align software (formerly ToolWatch) because it features best-in-class asset management options its team knew would improve their project flows. And right before COVID struck, they launched an 85,000 sq. ft. off-site construction facility, where they design, manufacture, fabricate, and assemble building elements to support the rapid speed of and efficient construction of a permanent structure.

The Problem

Tonn and Blank’s operations team reached out to April Brown to help resolve a bottleneck and increase the efficiency of their process for collecting equipment time used for job costing purposes. Together they identified improvement opportunities and addressed them with a combination approach of looking at technology and process improvement—the solution needed to improve the workflow was readily available.

We interviewed April Brown, Tonn and Blank’s process improvement manager and a 20-year veteran of the construction industry, to learn about a recent operational challenge that led Tonn and Blank to increase its utilization of Align.

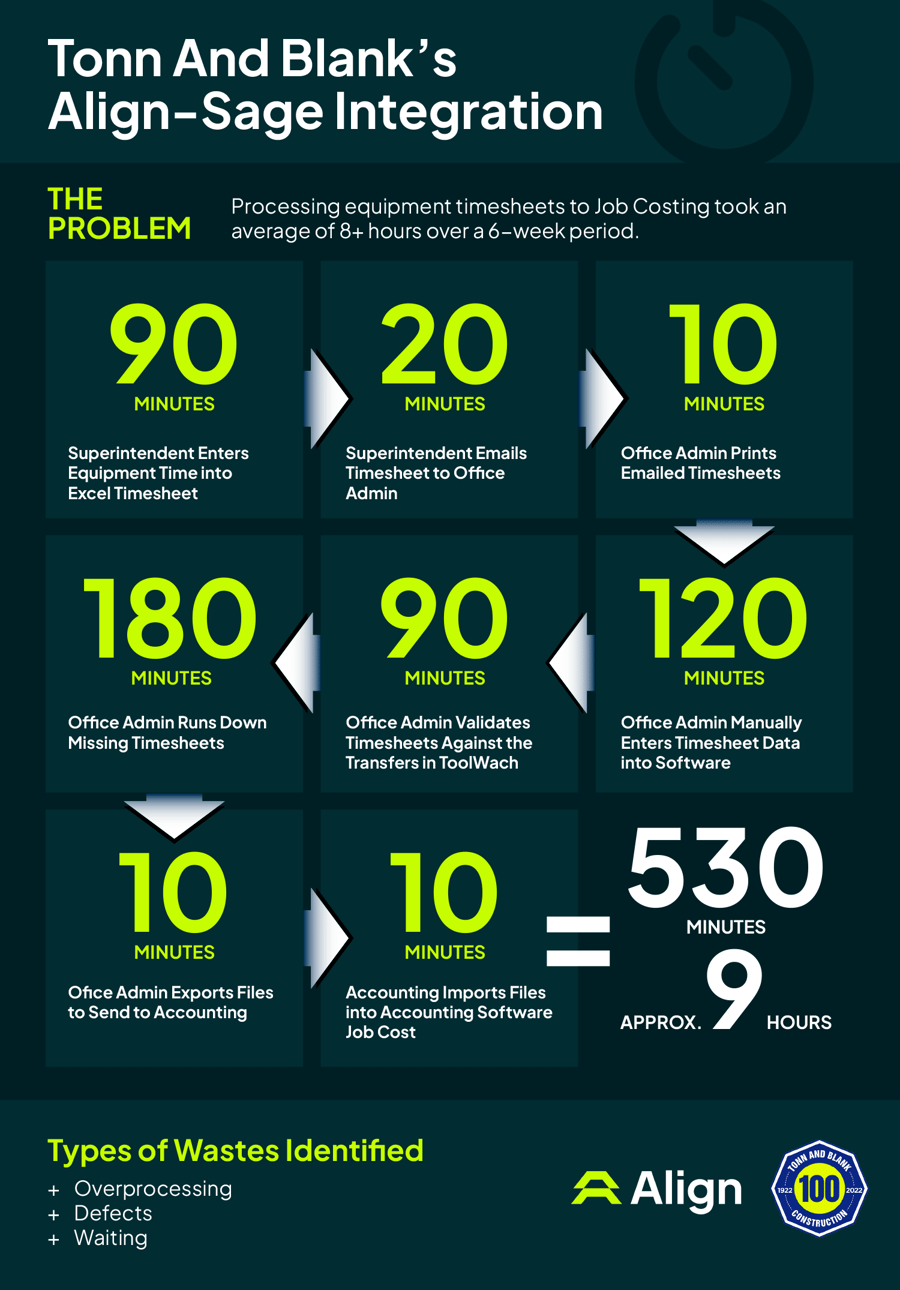

It took Tonn and Blank 8+ hours weekly, over a 6-week period, to manually process equipment timesheets into their accounting system to cost and bill their clients accurately.

First, superintendents had to manually log equipment usage in Excel timesheets and email them to the office. Then, once the office admin tracked down all timesheets, the information was validated against the transfers recorded in Align and reentered into their accounting software, Sage 300 CRE, equipment module. Finally, those files were exported and sent to accounting to be uploaded into Sage 300 CRE's job cost module. Here’s what the process looked like:

In all, it was an 8-step process that caused numerous problems. “We were over-processing information,” said April Brown. “We were having rework because we didn’t have transparency between the superintendents and the project managers, who didn’t know what would hit jobs. Not to mention, things would get missed off those timesheets. And then there was the waiting, which was a huge bottleneck for the office.” The cost was too high, and the operations team was eager for new software to streamline the process flow.

The Solution

Discovery! April began by asking the important questions: “What does the problem look like now - current state? How does the process need to work - desired state?”

April knew she had to examine all steps involved and identify the gaps. Only then could she uncover and fix the root cause of the bottleneck.

April observed the process for several weeks and met with all the teams and individuals involved, and it soon became apparent that this was, at the root, a process and integration issue. During step five of the process, the office admin was validating the equipment timesheets against the transfers recorded in Align, which meant they already had the data to populate their timesheets in one of their systems. Align was also used to get tools and equipment to their job sites.

The team needed a way to process that data and import it into Sage 300 CRE, which would eliminate both the manual entry and overprocessing of information.

As a powerful construction operations platform, Align integrates with other leading construction platforms, including ERP and accounting systems like Sage. The team at Align had long ago come to the same conclusion as Tonn and Blank: the equipment data tracked in the Align platform has value to more than just the people who handle tools and equipment. Teams ranging from project management to procurement to job costing could benefit from access to the data. So, where there was a use case, Align expanded the platform to enable it, thereby optimizing the operational flows of our customers.

Shortly after discovering Align’s expanded capabilities, Tonn and Blank implemented a new process that integrated Align’s job costing module with Sage 300 CRE, reducing the number of steps by more than half.

Every Friday, automated equipment usage reports are generated by Align and pushed to the superintendents for review and verification. To keep the process moving, the superintendents know they have until the following Monday to identify any changes before the office admin adjusts and posts the equipment time in Align’s job cost module. This report is also shared with the project management team before posting. All that’s left to do is make any requested changes, post transactions in Align and import the spreadsheets into Sage.

The Result

The results were immediately obvious to everyone involved.

Over 7 hours weekly were shaved off the time to completion, and the yearly cost to Tonn and Blank was reduced by 80%.

Buy-in and change management can often be a sticking point when it comes to process change, but by educating system users on what was in it for them, April could roll out the new solution effectively. In addition to streamlining job costing, the Align/Sage integration streamlined the process of project setup and cost codes through the automatic import feature.

The operations team quickly recognized how much time they saved in several processes by working directly in Align and utilizing the Sage integration—time they could use to focus on critical tasks in the field. All stakeholders are grateful for less rework, time waiting on information, and transparency at their fingertips.

April lives for these aha moments that transform operations. Her message to others who want to begin implementing lean construction principles at their own company is to embrace opportunities like these.

“Don’t underestimate small improvements,” she says, “they add up to big gains and really increase your productivity and bottom line.”

If you are interested in learning more about how your organization can enact lean operations that save time and money, we encourage you to watch "Operating Lean: How Tonn and Blank Puts Lean Construction Into Practice," the on-demand webinar with April Brown.

This is one example of the many use cases Tonn and Blank uses Align to streamline their operations. And when your company is ready to implement a software solution that creates efficiencies in your own processes, remember, Align is built to enable lean operations.